Silk screen printing is a highly versatile labeling process that has grown increasingly popular for products that are frequently exposed to moisture, washing, and outdoor conditions. Today, silk screen printing has become one of the most widely used methods for printing images and text on a variety of products and materials. The durability and weatherproof nature of screen-printed designs make the method ideal for the creation of labels, branding, designs, and other details on glassware and plastic bottles.

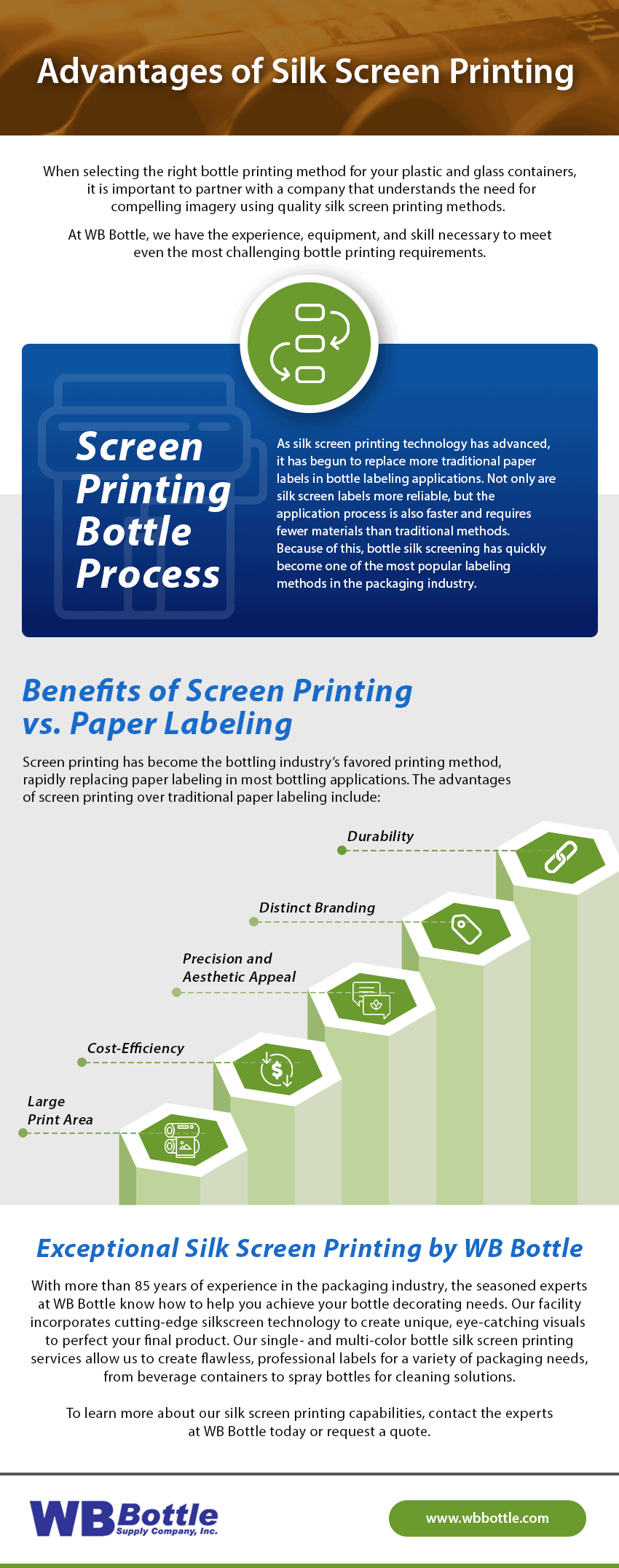

When selecting the right bottle printing method for your plastic and glass containers, it is important to partner with a company that understands the need for compelling imagery using quality silk screen printing methods. At WB Bottle, we have the experience, equipment, and skill necessary to meet even the most challenging bottle printing requirements.

Screen Printing Bottle Process

As silk screen printing technology has advanced, it has begun to replace more traditional paper labels in bottle labeling applications. Not only are silk screen labels more reliable, but the application process is also faster and requires fewer materials than traditional methods. Because of this, bottle silk screening has quickly become one of the most popular labeling methods in the packaging industry.

The silkscreening process involves pressing specialized ink through photographically treated silk or synthetic material onto your plastic or glass container. The material is held tightly in a wood or aluminum frame, and a coating is applied to the areas that should not print. This creates a stencil through which ink can be forced against the bottle using a squeegee. Depending on the needs of your application, silk screen designs can be created in multiple colors, with various typefaces and flexible label dimensions.

Benefits of Screen Printing vs. Paper Labeling

Screen printing has become the bottling industry’s favored printing method, rapidly replacing paper labeling in most bottling applications. The advantages of screen printing over traditional paper labeling include:

Durability

When it comes to durable labeling, screen printing is far more durable and long-lasting than paper labels. While paper labels easily show wear and tear due to scuffing and shelf contact, screen printing maintains a fresh appearance. In addition, exposure to moisture or the elements will not cause screen printed labels to degenerate, stain, or peel as paper labels do.

Distinct Branding

Screen printed bottles allow manufacturers to create a unique brand appearance that will stand out in any environment. You can personalize your design with compelling images, visually striking branding, color effects, and even metallic finishes. With almost 360° of printing area, you can easily merge your bottle’s aesthetic with attractive labels to create eye-catching products in any setting.

Precision and Aesthetic Appeal

Screen printing creates clear designs and shapes directly on the bottle, with exceptional precision. Your branding and design will be crisp and clean, with neat lines, clear words, and an impeccably smooth surface. With a wide range of colors and effects, you can rest assured that your final product will look exactly the way you pictured it.

Cost-Efficiency

Screen printing requires a lower initial investment than many traditional printing methods. In addition, it provides a higher return on investment, especially for small-scale production. The process requires fewer supplies, and you can ensure economical production by using only the amount of ink you need, for minimal material waste.

Large Print Area

Screen printing offers a greater printing area for your branding and labeling needs. Rather than adhering to standard label sizes based on the shape of your bottle, you can develop singular designs unrestricted by your container’s size and shape.

Exceptional Silk Screen Printing by WB Bottle

As packaging and labeling technology continues to advance, screen printing will continue to be at the forefront of the bottle labeling industry. At WB Bottle, we are committed to using the latest bottling and labeling technology. Our state-of-the-art screen printing equipment allows us to create custom decorations, branding, and imagery to make your glass and plastic bottles stand out in the crowd.

With more than 85 years of experience in the packaging industry, the seasoned experts at WB Bottle know how to help you achieve your bottle decorating needs. Our facility incorporates cutting-edge silkscreen technology to create unique, eye-catching visuals to perfect your final product. Our single- and multi-color bottle silk screen printing services allow us to create flawless, professional labels for a variety of packaging needs, from beverage containers to spray bottles for cleaning solutions.

Our knowledgeable graphic design team will start by helping you find the printable area of your bottle. With your artistic concept in mind, our team works closely with you throughout the design and manufacturing process, creating mock-ups and models to help make your concept a reality. No matter what your needs, we have the experience and technology to make your product concept a reality.

To learn more about our silk screen printing capabilities, contact the experts at WB Bottle today or request a quote.