Bottle Cap Liner Overview

If an application calls for the use of a bottle or container, it’s important to select the right closure. One aspect of a closure is the liner used for it. Liners are an essential aspect of the closure because they help improve product longevity and increase safety. For example:

- Tamper-evident seals help keep food from spoiling and make it evident if someone has accessed what is inside

- Certain liners increase the shelf life of food, chemicals, and personal care products

Some products react poorly to different liner materials. Every application will benefit from a specific bottle cap liner; brands only need to choose the liner that’s compatible and best for their products.

As always, be sure to test your product with the liner you choose to be sure they are compatible.

Bottle Resin Compatibility

| Polyster | Polyster | Polyvinyl Chloride | Barex | Polyethylene | Polyprpylene | ||

|---|---|---|---|---|---|---|---|

| Properties | PET | PETGC | PVC | Barex | HDPE | LDPE | PP |

| Clarity | Clear | Clear | Clear | Clear | Opaque | Opaque | Translucent |

| Rigidity /Stiffness | Moderate to High | Moderate to High | Moderate to High | High | Moderate | Low | Moderate to High |

| Impact Resistance | Good to Excellent | Good | Fair to Good | Fair to Good | Good to Excellent | Excellent | Poor to Good |

| Low Temp. Impact Resistance | Fair to Good | Poor | Poor to Fair | Poor to Fair | Good to Excellent | Excellent | Poor to Good |

| Stress Crack Resistance | Good to Excellent | Good | Good to Excellent | Good to Excellent | Good to Excellent | Good | Good to Excellent |

| Moisture Barrier | Fair to Good | Fair to Good | Fair | Fair | Good to Excellent | Good | Good to Excellent |

| Oxygen Barrier | Good | Good | Good | Excellent | Poor | Good | Good |

| Scuff Resistence | Poor to Fair | Poor to Fair | Poor to Fair | Poor to Fair | Very Good | Very Good | Very Good |

| Resistance to: | |||||||

| Acids | Fair to Good | Fair to Good | Good to Excellent | Fair to Good | Fair to Very Good | Fair to Very Good | Fair to Good |

| Alcohols | Good | Good | Good to Very Good | Good | Good | Good | Good |

| Alkalis | Poor to Fair | Poor to Fair | Good to Very Good | Good | Good to Very Good | Very Good | |

| Mineral Oils | Good | Good | Good | Excellent | Fair | Poor to Fair | Fair |

| Solvents | Good | Good | Fair to Good | Excellent | Poor to Fair | Poor to Fair | Poor to Good |

| Heat | Poor to Fair | Poor to Fair | Poor to Fair | Poor to Fair | Good | Fair | Good |

| Cold | Good | Good | Fair | Fair | Exccellent | Exccellent | Poor to Fair |

| Sunlight | Good | Good | Poor to Good | Poor to Good | Fair | Fair | Fair |

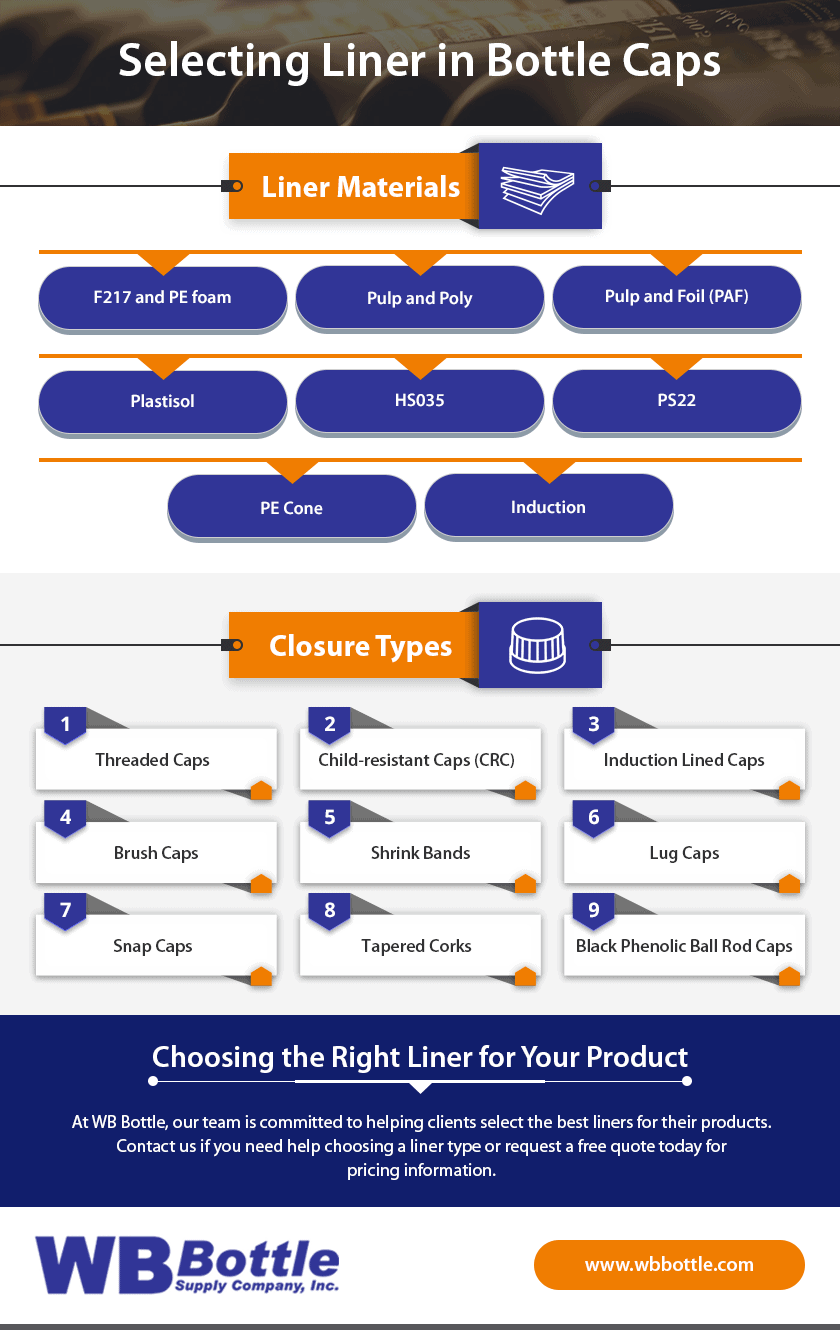

Liner Materials

- F217 and PE foam: White, foam-type liner; PE is the generic version of F217 and both are generally good for liquid products.

- Pulp and Poly: Liners made of two materials; the pulp is cardboard-like and faces the cap while the polyvinyl chloride (PVC) faces the product; suitable for solid and liquid food items.

- Pulp and Foil (PAF): Liners made of two materials; pulp is cardboard-like and faces the cap; the product-facing layer is foil; these liners are popular for solid and powdered products.

- Plastisol: Foamy, PVC component that forms a hermetic seal with the lip of a bottle; usually used for glass bottles and jars.

- HS035: Specialty, induction seal liners; liners stick to bottles to create tamper-evident seals; usually appear silver on the product-facing side and printed with protective information on the consumer-facing side.

- PS22: Pressure-sensitive liners with tamper-evident properties; applied through pressure and offers good sealing properties for dry products.

- PE Cone: Usually used with glass or amber pour-out glass bottles; cone-shaped and creates a seal on the lip of a bottle; ideal for carbonated products and essential oils.

- Induction: Uses a heat-sealing foil laminate and creates a hermetic seal

Other liner materials also include Teflon PTFE, Polyseal, and Poly vinyl.

Closure Types

- Threaded caps: The interiors of threaded caps have spiraling, uninterrupted threads; the threads match up with the neck finish of compatible containers.

- Child-resistant caps (CRC): These caps require dissimilar motions to open, which makes it difficult for children to access what’s inside; you have to push down on a CRC cap while turning it clockwise to open.

- Induction lined caps: There are several layers in an induction liner: wax, foil, pulpboard, and polymer coating; they create hermetic seals.

- Brush caps: Brush caps have two primary components: a screw cap and a plastic rod attached to the inside. There are bristles at the end of the rod to help with product application.

- Shrink bands: Shrink bands are tamper-evident and, usually, perforated to facilitate easy removal; they are made of PVC plastic.

- Lug caps: Lug caps are used with lug-finish containers; they have non-continuous threads.

- Snap caps: Snap caps don’t use threads; instead, they have closures held in place by a depressed or raised circle around the closure.

- Tapered corks: Tapered cork stoppers are natural and decrease in diameter from top to bottom.

- Black phenolic ball rod caps: Black phenolic ball rod caps have PE plastic rods attached on the inside; at the ends of these rods, there are round protrusions for applying product.

Choosing the Right Liner for Your Product

At WB Bottle, our team is committed to helping clients select the best liners for their products. Contact us if you need help choosing a liner type or request a free quote today for pricing information.